What is Bamboo?

Bamboo is a fast-growing, renewable perennial plant that thrives in various

climates, making it an ideal resource for biomass energy. Known for its

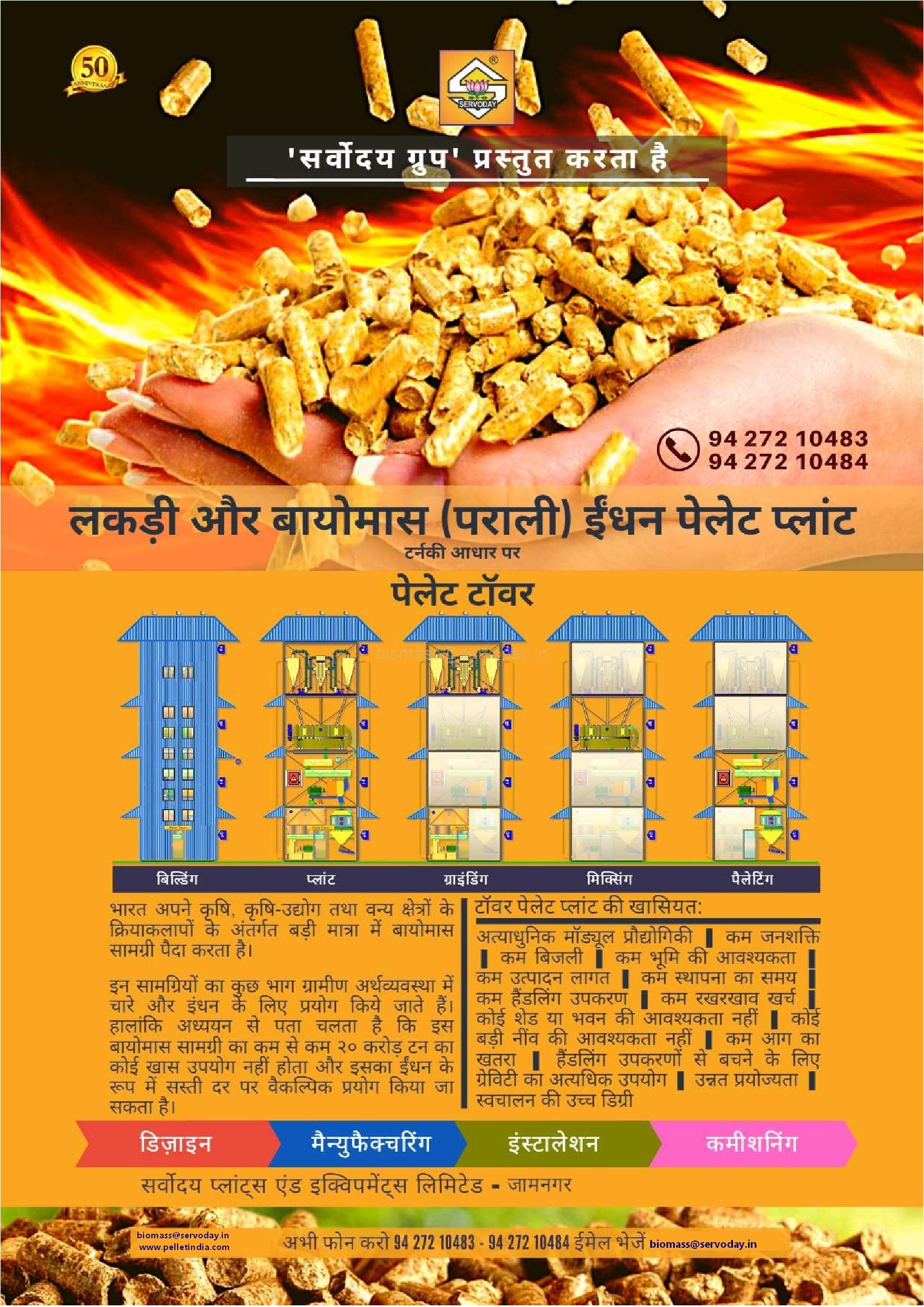

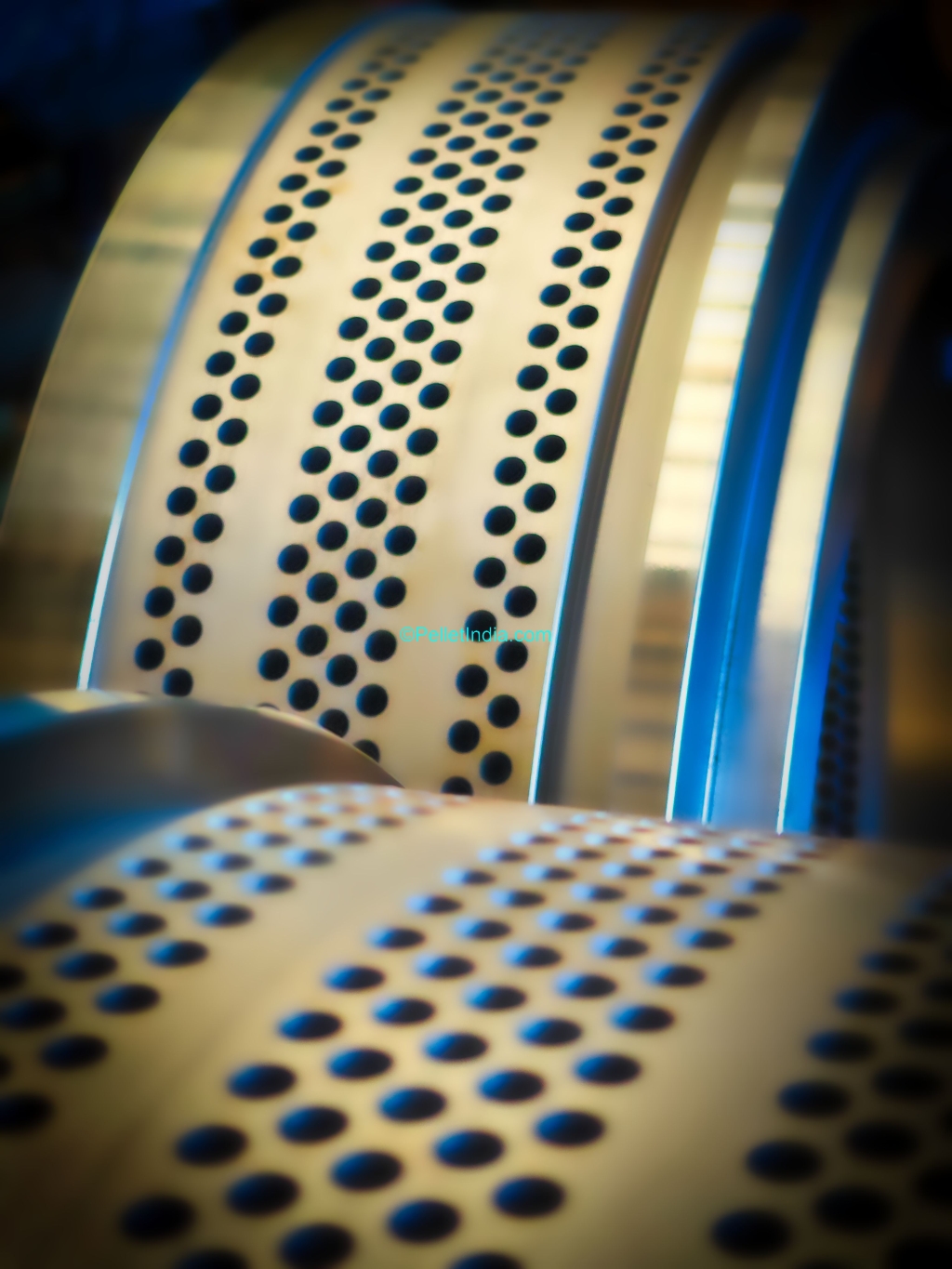

durability and versatility, bamboo is widely cultivated for pellet

production, biomass fuel, and industrial applications.

Renewable & Green Energy

Ditch the fossil fuels! Bamboo is a highly renewable and carbon-neutral

biomass source, providing a continuous and eco-friendly alternative for

pellet production and clean energy generation. Its low environmental

impact makes it a preferred choice for sustainable industries.

Fast Growth & High Yield

Time is money, and bamboo grows at incredible speeds—up to 3 feet per

day! This high-yield crop ensures continuous biomass supply for bamboo

chips and pellets, outperforming traditional wood-based fuels in

sustainability and efficiency.

Sustainable & Earth-Friendly

Sustainability starts with the soil. Bamboo prevents soil erosion,

enhances biodiversity, and improves carbon sequestration. Its deep root

system helps maintain soil fertility while requiring minimal water and

fertilizers, making it an environmentally responsible choice for biomass

energy production.