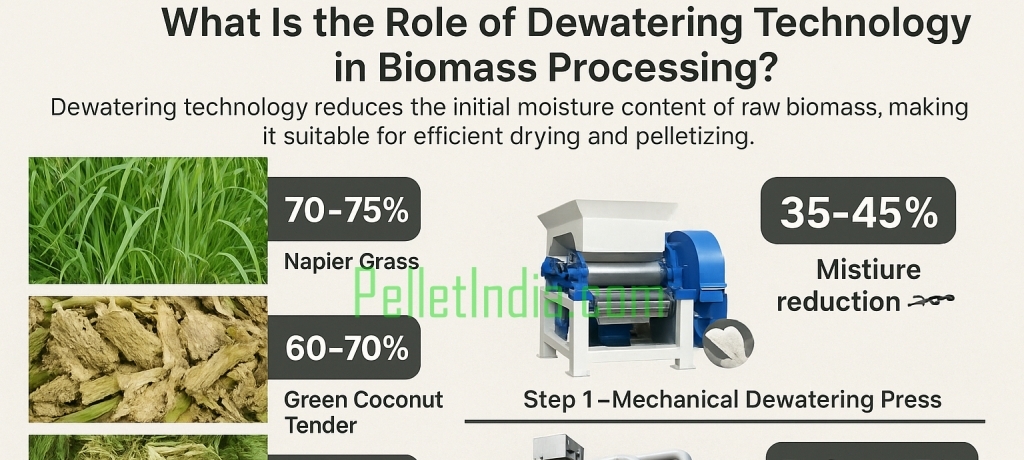

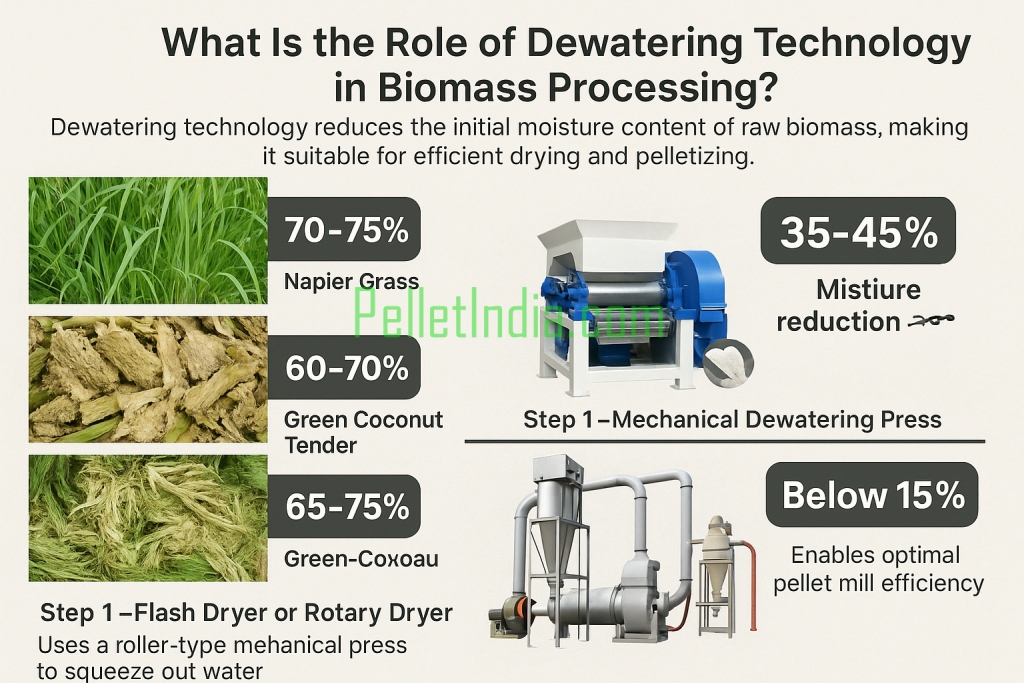

Dewatering technology plays a crucial role in the biomass pellet-making process by reducing the initial moisture content of raw biomass materials, making them suitable for efficient drying and pelletizing.

Many high-moisture raw materials—such as Napier Grass, sugarcane bagasse, and green coconut husk—contain 65% to 75% moisture, which is too high for direct pellet production. To achieve quality and durability in the final pellets, the moisture must be reduced to:

1. Initial Moisture Content (Raw Material):

2. Step 1 – Mechanical Dewatering Press:

3. Step 2 – Flash Dryer or Rotary Dryer:

PelletIndia.com, a division of Servoday Plants & Equipments Limited, delivers advanced dewatering and drying solutions specifically engineered for biomass materials.

We offer:

Our systems:

India is poised to be a global leader in green energy. With Napier Grass offering 150–200 tons/acre/year yield, it’s a sustainable feedstock for:

Its adaptability, fast regrowth, and multiple revenue streams make Napier Grass a cornerstone crop in India’s green economy and carbon reduction goals.

📞 Contact Us for Biomass Solutions

📍 Servoday Plants & Equipments Ltd

📞 +91 9427210483 | +91 9427210484

📧 [email protected]

🌐 www.PelletIndia.com

👤 Contact Person: Sanjay Masuria

📲 WhatsApp: +91 9427210483

From Concept to Commissioning. We are with You.

Our policy is simple and transparent:

No undersized parts, no fraud, no fake components—genuinely serving since 1969. 🚀🔥

Moisture reduction values vary based on raw material, ambient environment, and system configuration. For best results, consult with our engineers at PelletIndia.