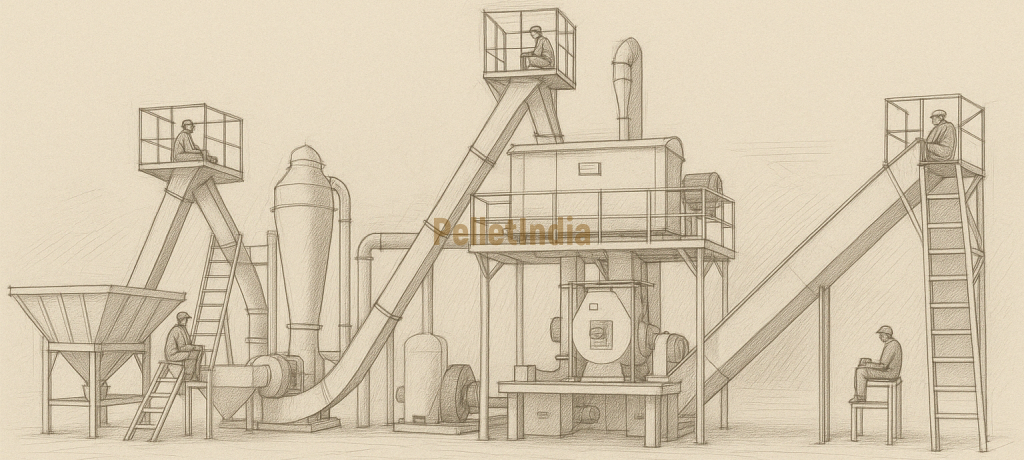

🌱 Inside a PelletIndia Fully Automated Biomass Pellet Plant: Key Machinery & Layout PelletIndia’s 5 TPH Fully Automated Biomass Pellet Plant is a cutting-edge facility designed for high efficiency, minimal human intervention, and consistent pellet quality. This real-world setup integrates smart automation, heavy-duty equipment, and an energy-efficient layout to ensure 24/7 operation with only 2 operators per shift .

🔧 Key Machinery in the 5 TPH Fully Automated Pellet Plant:

Hydraulic Moving Floor Feeding Hopper with Level Sensors – Controls flow rate to the vibrating screen.Vibrating Screen – Removes impurities from biomass.Chain Conveyor System – Heavy-duty transport for raw material across the layout.Flash Dryer (Optional: Rotary Dryer) – Reduces moisture to optimal levels for pelletizing.Magnetic Separator – Extracts ferrous materials for equipment protection.Tear Drop Hammer Mill – Pulverizes raw biomass into fine particles.Air Aspiration System – Reduces dust, increases hammer mill efficiency.Ribbon Mixer – Ensures uniform blending of raw material for consistent pellets.Feeder Dosing System – Automatically meters material into the pellet mill.Ring Die Pellet Mill Pellet Cooler (Counter-Flow Type) – Brings pellet temperature close to ambient.Screening & Dedusting Unit – Removes fines from finished pellets.Conveyors to Storage – Transports pellets to silos or jumbo bag stations.Jumbo Bag Filling Station – Automated bagging and weighing system.Centralized Control Panel (PLC + HMI) – Full plant monitoring, automation, alarms, data logging.🌍 Layout Features:

Modular Design : Easy maintenance and expansion.Fully Enclosed Conveying : Dust-free environment.Optimized Flow Path : Reduces energy usage and transport time.Energy-Efficient Motors & VFDs : Lower operational cost.💡 Labor & Efficiency Highlights:

Only 2 operators needed per shift. Remote monitoring and automatic alerts via PLC/HMI.Auto-start/stop sequencing reduces downtime and manual errors.Pre-installed sensors optimize drying and pelletizing based on moisture and feed rate.