upto 5.0 Tons Per Hour

Process Function The Coal Pellet Mill is designed to transform fine coal dust, coke powder, and other carbon-based residues into high-density fuel pellets or briquettes. The process enhances combustion efficiency, reduces dust pollution, and improves fuel handling for industrial applications. With advanced compression technology, the machine forms uniform, durable coal pellets with optimized moisture content, […]

Process Function

The Coal Pellet Mill is designed to transform fine coal dust, coke powder, and other carbon-based residues into high-density fuel pellets or briquettes. The process enhances combustion efficiency, reduces dust pollution, and improves fuel handling for industrial applications.

With advanced compression technology, the machine forms uniform, durable coal pellets with optimized moisture content, making them ideal for energy production, metallurgy, and industrial heating. The process also supports cleaner emissions by enabling controlled combustion.

Technical Features

| Feature | Specification |

| Capacity | 1 – 5 TPH |

| Pellet Diameter | 8mm – 20mm |

| Compression Type | High-Pressure Roller Press |

| Binder Requirement | Optional, based on raw material composition |

| Moisture Content | 8% – 15% for optimal performance |

| Material Construction | Alloy Steel Rollers, Heavy-Duty Cast Iron Body |

| Power Consumption | 45 – 250 kW, based on capacity |

| Automation Level | Fully Automatic / Semi-Automatic |

Application

✅ Power Generation – Fuel pellets for thermal power plants

✅ Metallurgical Industry – Reduces waste coal dust & improves furnace efficiency

✅ Cement Kilns – Alternative fuel for high-temperature processing

✅ Industrial Boilers – Clean and efficient burning fuel alternative

✅ Domestic Heating – High-energy coal pellets for household stoves

Process Raw Materials

📞 Contact Us for Biomass Solutions

📍 Servoday Plants & Equipments Limited

📞 +91 9427210483 | +91 9427210484

📧 [email protected]

🌐 www.PelletIndia.com

👤 Contact Person: Sanjay Masuria

📲 WhatsApp: +91 9427210483

Compact & Portable Bamboo and Wood Biomass Mobile Pellet Plant – On-Site Biomass Processing Pr...

Conventional Bamboo and Biomass Pellet Plant – Efficient & Cost-Effective Biomass Fuel Solutio...

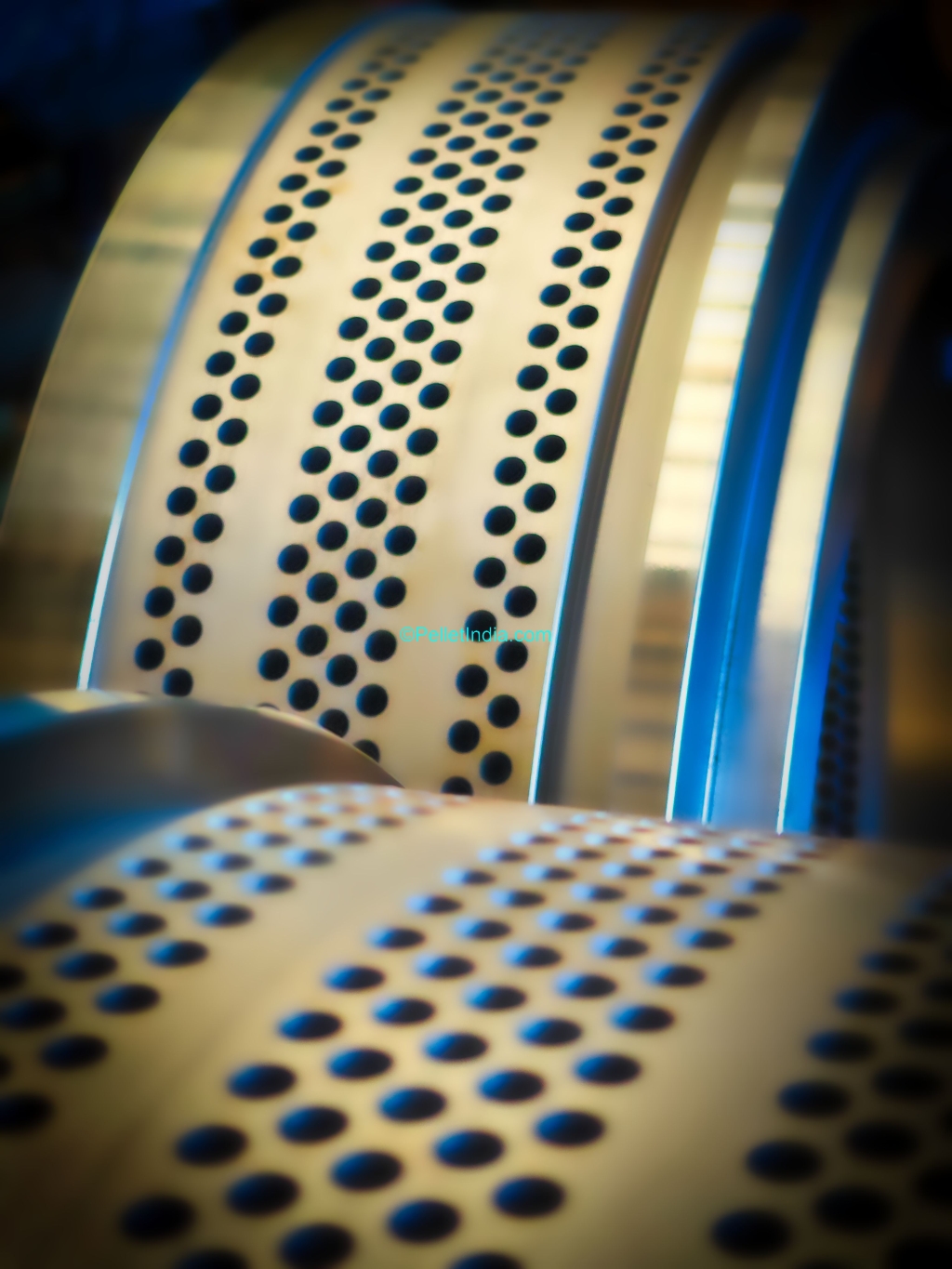

Process Function The Dual Track Ring Die is a high-efficiency die designed for pellet mills, enhanci...

Process Function A drum chipper is an industrial-grade machine designed to efficiently process logs,...