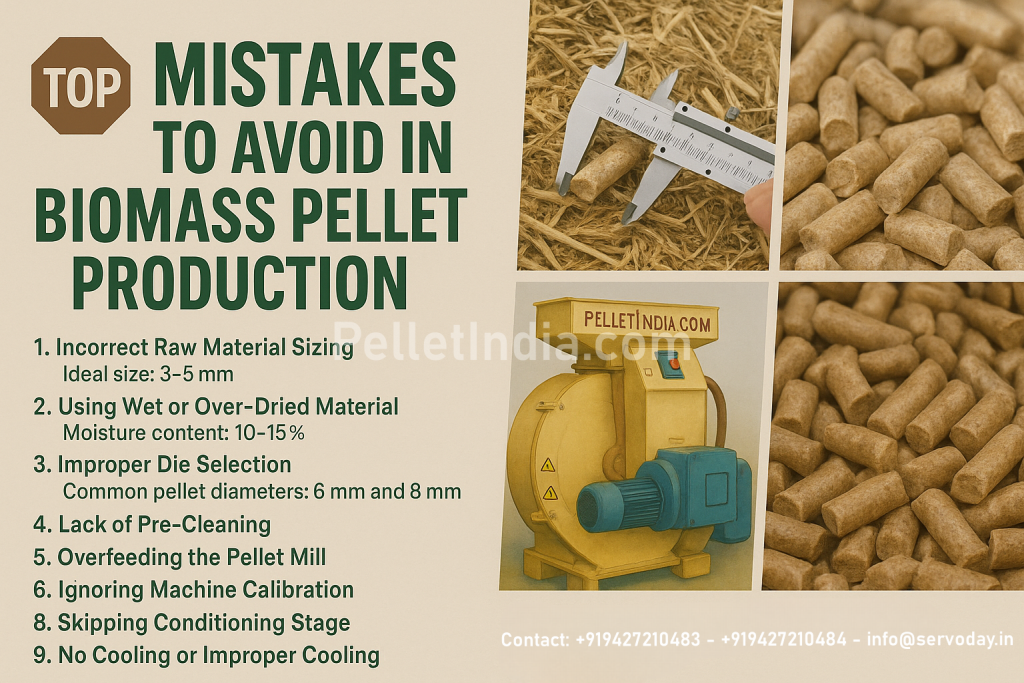

Producing high-quality biomass pellets requires precision at every stage. From raw material handling to machine calibration, minor mistakes can lead to poor pellet quality, machine breakdowns, and wasted resources. Here are the top 10 common mistakes you should avoid:

1. Incorrect Raw Material Sizing

2. Using Wet or Over-Dried Material

3. Improper Die Selection

4. Lack of Pre-Cleaning

5. Overfeeding the Pellet Mill

6. Ignoring Machine Calibration

7. Skipping Conditioning Stage

8. No Cooling or Improper Cooling

9. Neglecting Lubrication

10. Lack of Quality Control

✅ Pro Tip:

Use properly dewatered, sized (3-5 mm), and moisture-controlled biomass for best pellet results using a 6 mm or 8 mm ring die setup.

📞 Contact Us for Biomass Solutions

📍 Servoday Plants & Equipments Ltd

📞 +91 9427210483 | +91 9427210484

📧 [email protected]

🌐 www.PelletIndia.com

👤 Contact Person: Sanjay Masuria

📲 WhatsApp: +91 9427210483

From Concept to Commissioning. We are with You.

Our policy is simple and transparent:

No undersized parts, no fraud, no fake components—genuinely serving since 1969. 🚀🔥