📝 Description:

Uttar Pradesh, a leading agricultural and industrial state, offers immense opportunities for biomass pellet production. With government support for co-firing biomass pellets in thermal power plants (TPPs), setting up a pellet plant near NTPC and private power stations ensures guaranteed offtake, eco-compliance, and high returns.

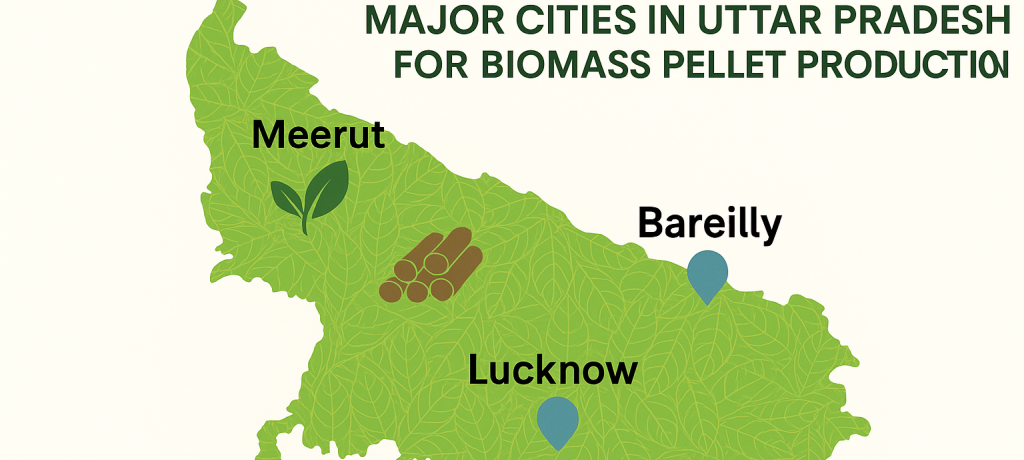

📍 1. Meerut

Biomass: Wheat straw, mustard stalk, sugarcane trash

Availability: ~1.2 million tons/year

Nearby Power Plants:

📍 2. Bareilly

Biomass: Rice husk, sugarcane tops, wheat husk

Availability: ~1.0 million tons/year

Nearby Power Plants:

📍 3. Varanasi

Biomass: Paddy straw, cotton stalks, wheat husk

Availability: ~900,000 tons/year

Nearby Power Plants:

📍 4. Lucknow Region (including Barabanki, Sitapur, Rae Bareli)

Biomass: Sugarcane trash, wheat straw, rice husk

Availability: ~1.5 million tons/year

Nearby Power Plants:

📍 5. Gorakhpur

Biomass: Paddy straw, mustard stalk, sugarcane trash

Availability: ~800,000 tons/year

Nearby Power Plants:

📍 6. Kanpur (with Unnao, Etawah, Auraiya belt)

Biomass: Rice husk, wheat straw, mustard husk

Availability: ~1.3 million tons/year

Nearby Power Plants:

✅ Summary Table

| City | Biomass (Tons/Year) | Key Biomass Types | Nearby Power Plants (MW) |

| Meerut | 1.2 million | Wheat Straw, Sugarcane Trash | NTPC Dadri (1,820), Harduaganj (665), Rosa (1,200) |

| Bareilly | 1.0 million | Rice Husk, Mustard Husk | Rosa (1,200), Harduaganj (665) |

| Varanasi | 0.9 million | Paddy Straw, Cotton Stalk | NTPC Tanda (2,200), Meja (1,320), Vindhyachal (4,760 – nearby MP) |

| Lucknow | 1.5 million | Sugarcane Trash, Rice Husk | NTPC Unchahar (1,550), Meja (1,320), Ghatampur (1,980) |

| Gorakhpur | 0.8 million | Paddy Straw, Sugarcane Trash | NTPC Tanda (2,200), Lalitpur (1,980) |

| Kanpur | 1.3 million | Mustard Husk, Wheat Straw | Ghatampur (1,980), Parichha (1,140), Auraiya (663 – gas) |

🔧 How PelletIndia Supports Turnkey Pellet Plant Projects

PelletIndia.com, a division of Servoday Plants & Equipments Limited, delivers Made-in-India solutions with international quality standards for setting up complete biomass pellet plants. We provide end-to-end support to ensure high efficiency, compliance, and performance — from feasibility to commissioning.

✅ What We Offer:

🇮🇳 Proudly Made in India, Built to Global Standards

All our equipment, including the PelletIndia Ring Die Pellet Mill and Tear Drop Hammer Mill, is manufactured in India using precision engineering, international-grade components, and pressurized oil-lubricated gearboxes — ensuring long-term durability, high output, and compliance.

🎯 Strategic Benefits

All information provided is for general reference only. Biomass availability, locations, and related data are estimates and may vary due to regional and seasonal factors. No guarantees are made regarding accuracy or project outcomes. Independent verification is recommended before making any decisions.

📞 Contact Us for Biomass Solutions

📍 Servoday Plants & Equipments Ltd

📞 +91 9427210483 | +91 9427210484

📧 [email protected]

🌐 www.PelletIndia.com

👤 Contact Person: Sanjay Masuria

📲 WhatsApp: +91 9427210483

From Concept to Commissioning. We are with You.

Our policy is simple and transparent:

No undersized parts, no fraud, no fake components—genuinely serving since 1969. 🚀🔥