upto 5.0 Tons Per Hour

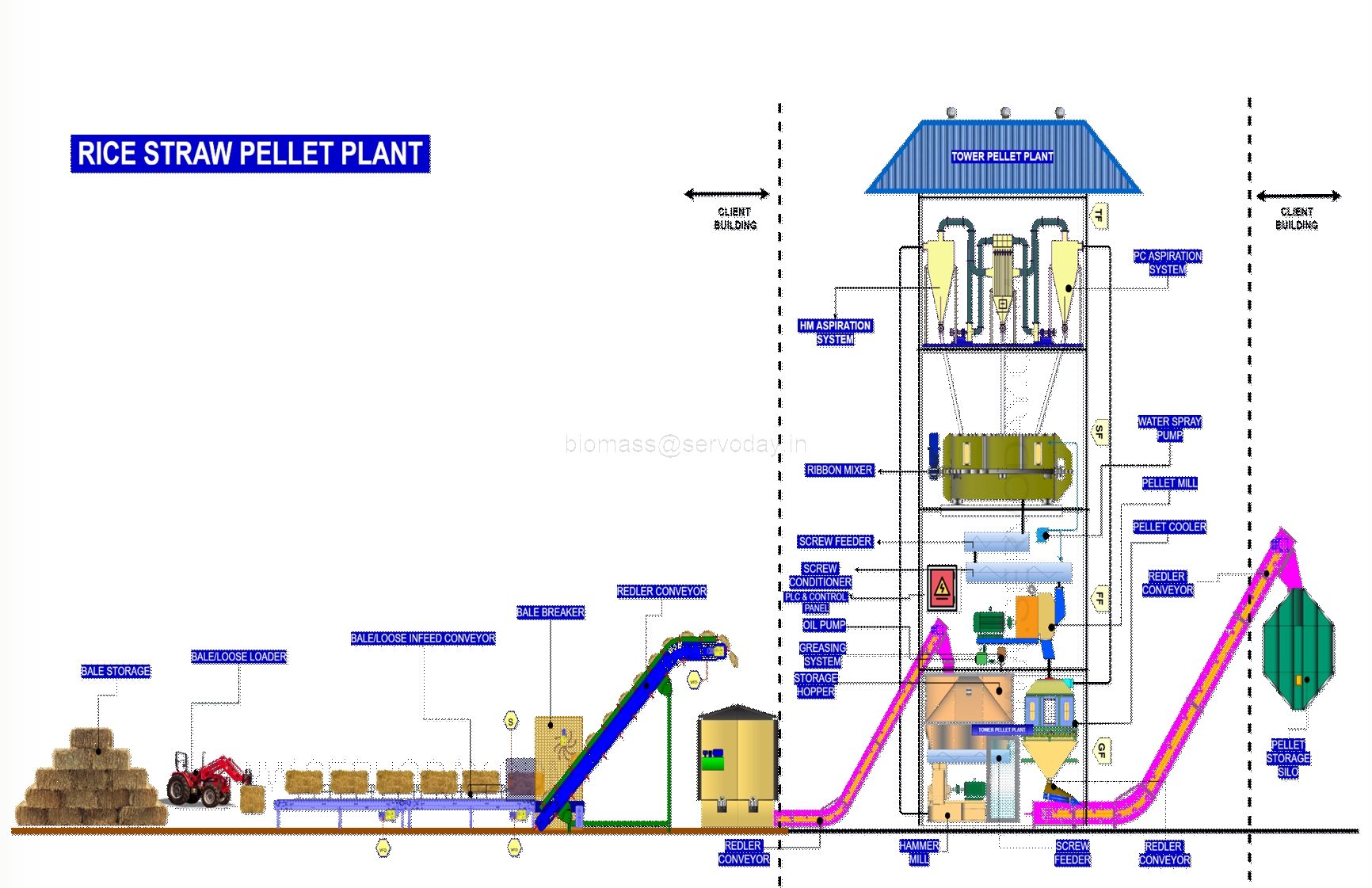

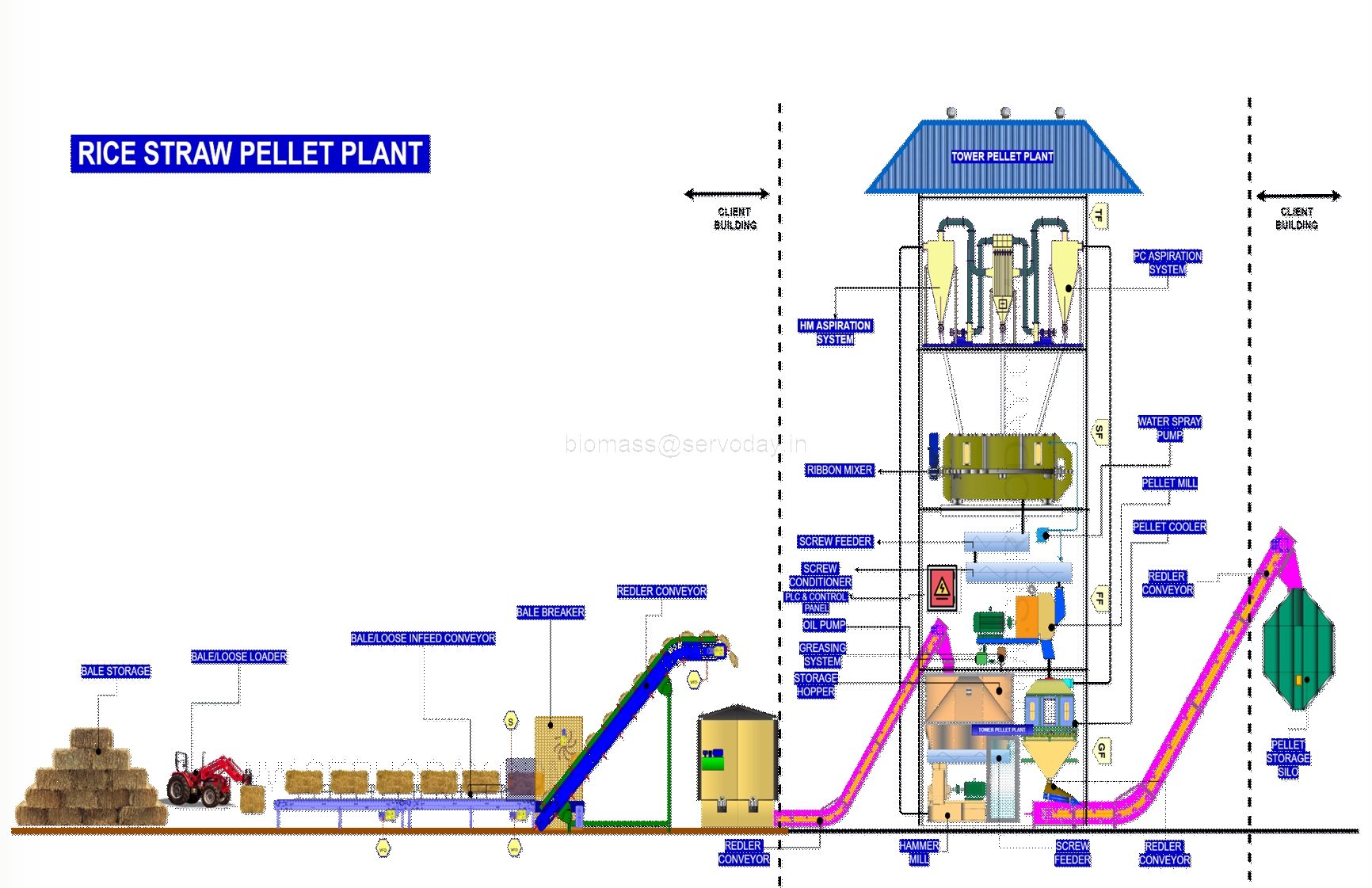

Bamboo & Biomass Tower Pellet Plant Process Function The Bamboo & Biomass Tower Pellet Plant is an innovative vertical-design system optimized for high-efficiency Bamboo & Biomass pellet production. By utilizing a space-saving tower structure, it reduces energy consumption and minimizes material handling requirements. This system ensures a streamlined workflow from raw material intake to finished […]

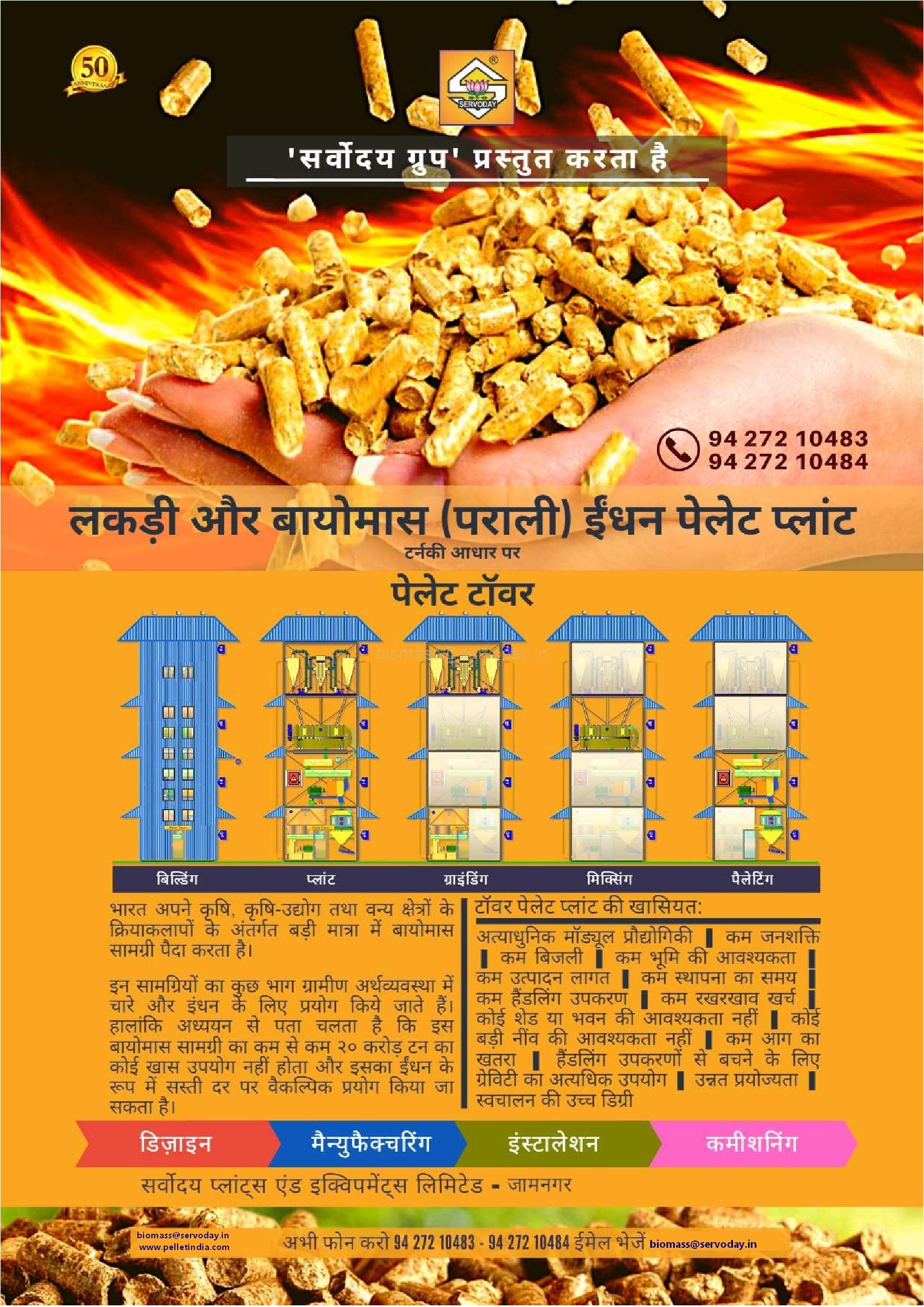

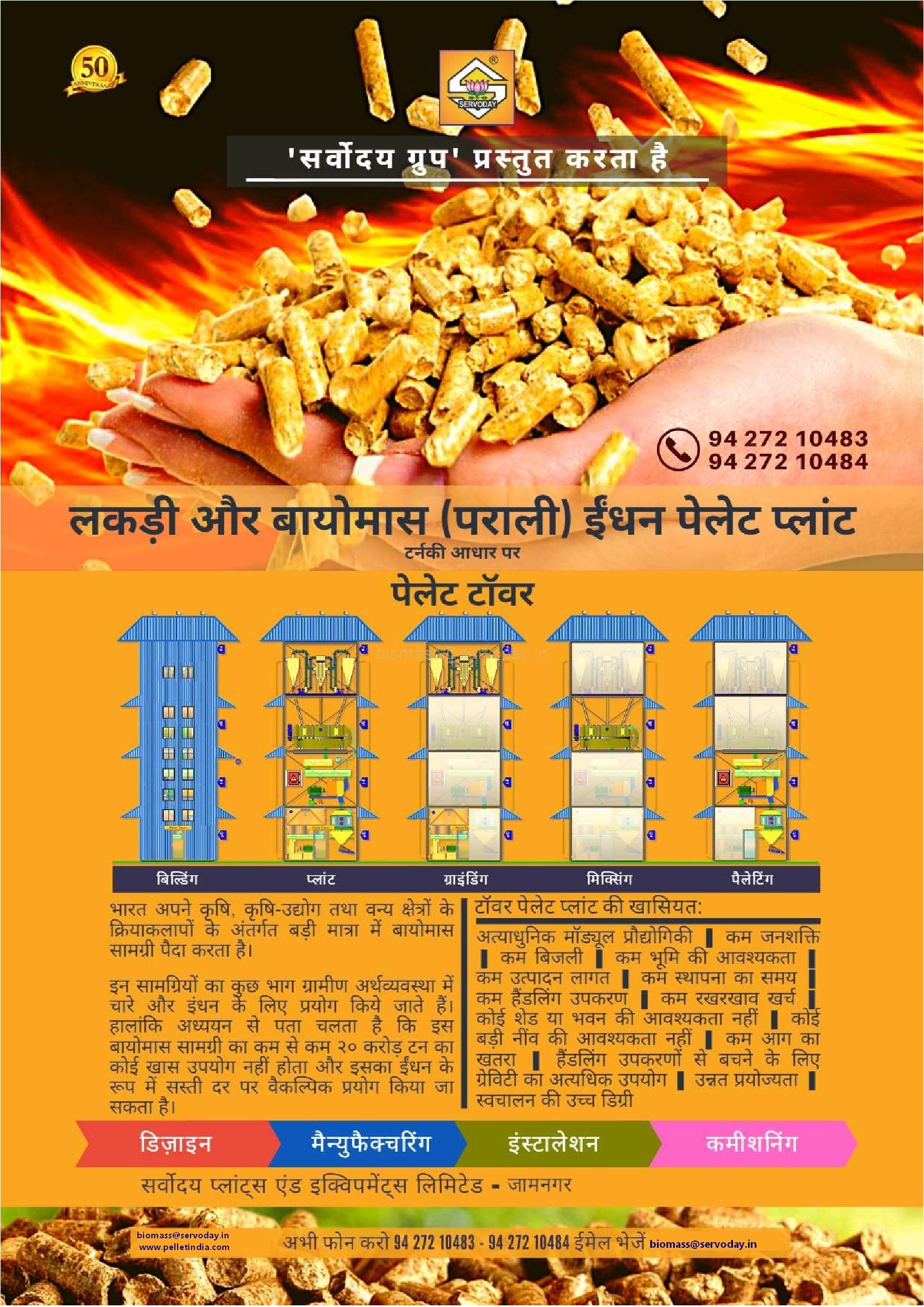

Bamboo & Biomass Tower Pellet Plant

Process Function

The Bamboo & Biomass Tower Pellet Plant is an innovative vertical-design system optimized for high-efficiency Bamboo & Biomass pellet production. By utilizing a space-saving tower structure, it reduces energy consumption and minimizes material handling requirements. This system ensures a streamlined workflow from raw material intake to finished pellet output, enhancing operational efficiency and product quality.

With an automated material flow and integrated drying, milling, and pelletizing processes, the Bamboo & Biomass Tower Pellet Plant offers a cost-effective and sustainable solution for large-scale Bamboo & Biomass pellet production. Its modular design allows flexibility for various Bamboo & Biomass feedstocks, ensuring high throughput and consistent pellet quality.

Technical Features

| Feature | Specification |

| Capacity | 1 – 5 TPH |

| Design | Vertical Tower Layout |

| Material Construction | Heavy-duty mild steel, stainless steel (contact parts), wear-resistant Hardox |

| Automation | Fully automated with PLC control |

| Energy Efficiency | Optimized power consumption for reduced operational costs |

| Pellet Size | 6mm, 8mm, 10mm, 12mm (customizable) |

| Dust Control | Integrated air aspiration system |

| Cooling System | Counterflow cooler for efficient pellet hardening |

| Drying System | Flash dryer or rotary dryer integration |

| Conveying System | Chain conveyor and bucket elevators for vertical material transport |

| Compression Ratio | Optimized for different Bamboo & Biomass feedstocks |

Application

✔️ Bamboo & Biomass Power Plants

✔️ Industrial Heating

✔️ Co-firing with Coal

✔️ Residential & Commercial Heating

✔️ Renewable Energy Projects

✔️ Bamboo & Biomass Fuel Manufacturing

Process Raw Materials

📞 Contact Us for Biomass Solutions

📍 Servoday Plants & Equipments Limited

📞 +91 9427210483 | +91 9427210484

📧 [email protected]

🌐 www.PelletIndia.com

👤 Contact Person: Sanjay Masuria

📲 WhatsApp: +91 9427210483

Process Function A drum chipper is an industrial-grade machine designed to efficiently process logs,...

Compact & Portable Bamboo and Wood Biomass Mobile Pellet Plant – On-Site Biomass Processing Pr...

Process Function The Boiler Biomass Fuel Feed System is designed for the efficient handling and cont...

Process Function A Pellet Carbonizing Plant is designed to convert biomass pellets into high-quality...