upto 10.0 Tons Per Hour

Process Function Biomass drying is a crucial step in pellet production, ensuring optimal moisture content for efficient combustion and pellet formation. The Rotary Dryer & Flash Dryer system rapidly reduces moisture levels in raw biomass materials, enhancing their energy value and processing efficiency. Designed for high-capacity drying, these dryers use controlled heat and airflow to […]

Process Function

Biomass drying is a crucial step in pellet production, ensuring optimal moisture content for efficient combustion and pellet formation. The Rotary Dryer & Flash Dryer system rapidly reduces moisture levels in raw biomass materials, enhancing their energy value and processing efficiency.

Designed for high-capacity drying, these dryers use controlled heat and airflow to remove moisture while maintaining the integrity of the biomass. This advanced drying process ensures consistent quality, lower drying time, and improved pellet durability for biomass fuel, animal feed, and industrial applications.

Technical Features

| Feature | Specifications |

| Drying Type | Rotary Dryer / Flash Dryer |

| Capacity Range | 1 – 10 TPH |

| Moisture Reduction | Up to 50% |

| Heating Source | Biomass Burner, Hot Air Generator, Steam, Gas |

| Airflow System | Counterflow or Co-current Drying |

| Temperature Control | Automated with Adjustable Heat Levels |

| Construction Material | Mild Steel, Stainless Steel 304/316 |

| Energy Efficiency | Optimized Air Circulation for Low Energy Consumption |

| Dust & Emission Control | Cyclone Separator, Wet Scrubber |

| Automation Level | Fully Automated / Semi-Automated Options |

Application

✅ Biomass Pellet Plants

✅ Wood Processing Industries

✅ Animal Feed Production

✅ Biofuel & Energy Sector

✅ Agro-Waste Processing

✅ Pharmaceutical & Chemical Industries

Process Raw Materials

📞 Contact Us for Biomass Solutions

📍 Servoday Plants & Equipments Limited

📞 +91 9427210483 | +91 9427210484

📧 [email protected]

🌐 www.PelletIndia.com

👤 Contact Person: Sanjay Masuria

📲 WhatsApp: +91 9427210483

Process Function Compressed pallets are high-strength, lightweight, and eco-friendly alternatives to...

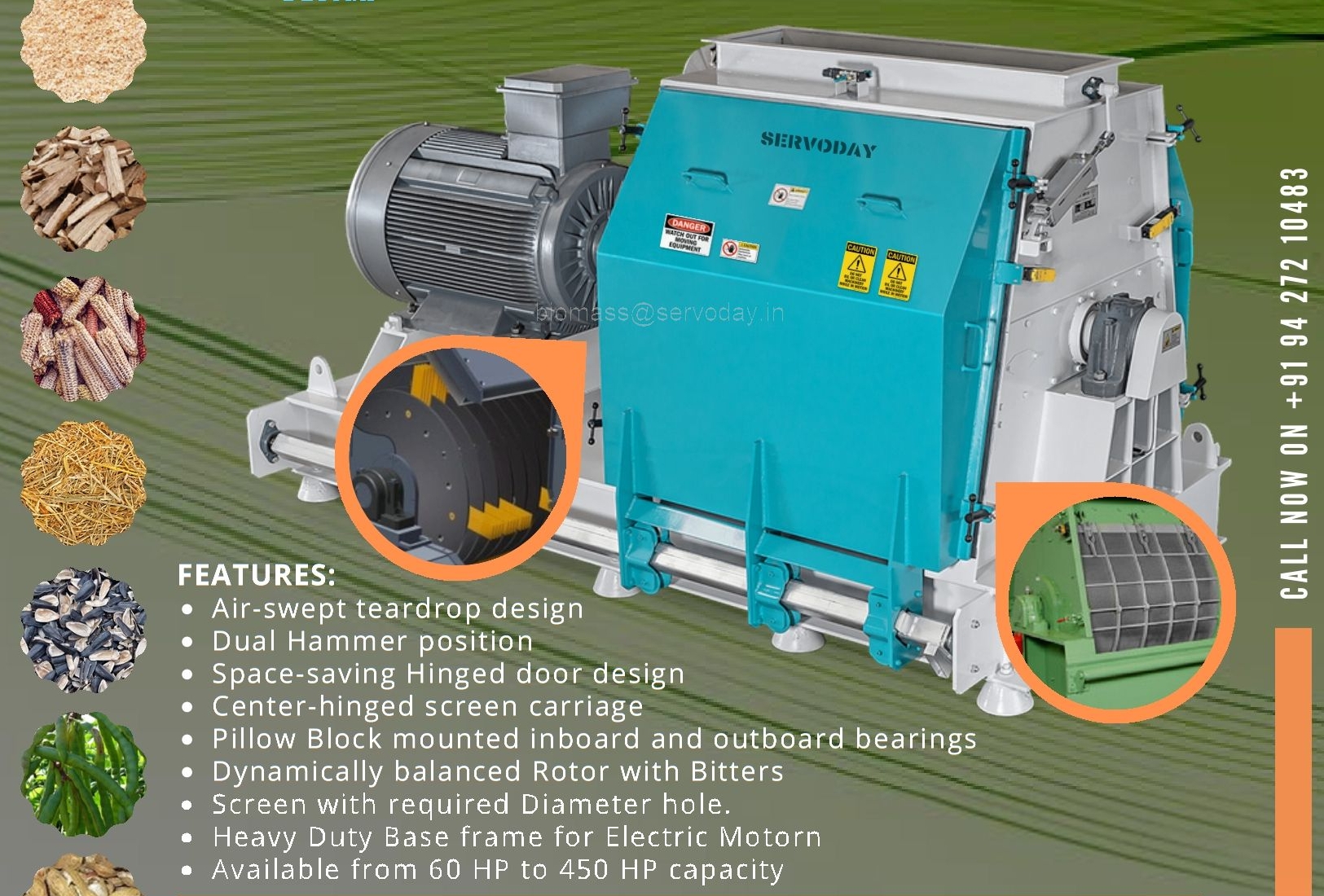

Process Function The Tear Drop Hammer Mill is designed for efficient size reduction of biomass, wood...

Process Function A drum chipper is an industrial-grade machine designed to efficiently process logs,...

Process Function The PelletIndia Twin Screw Breaker (Crusher) is designed to crush biomass briquette...