upto 10.0 Tons Per Hour

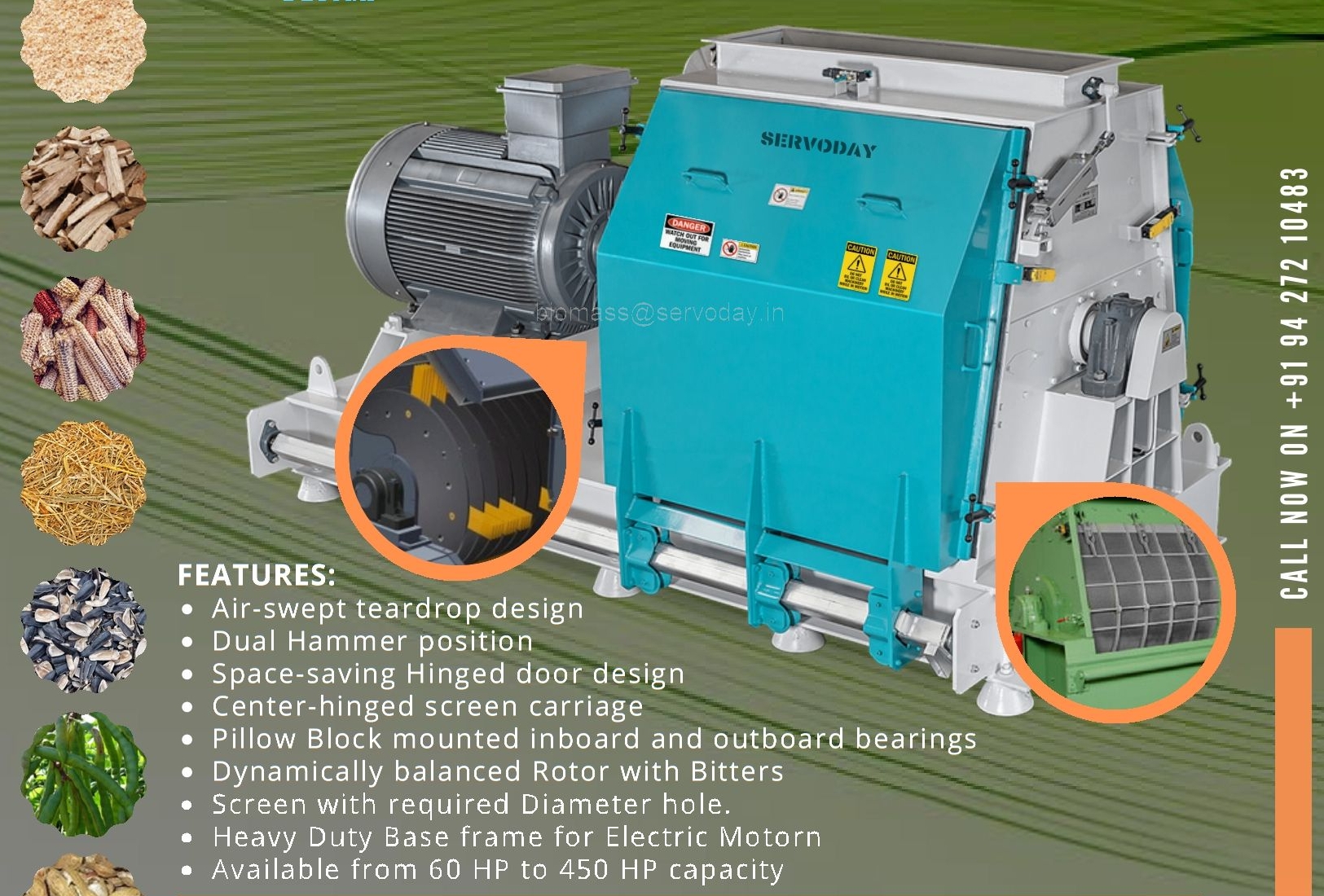

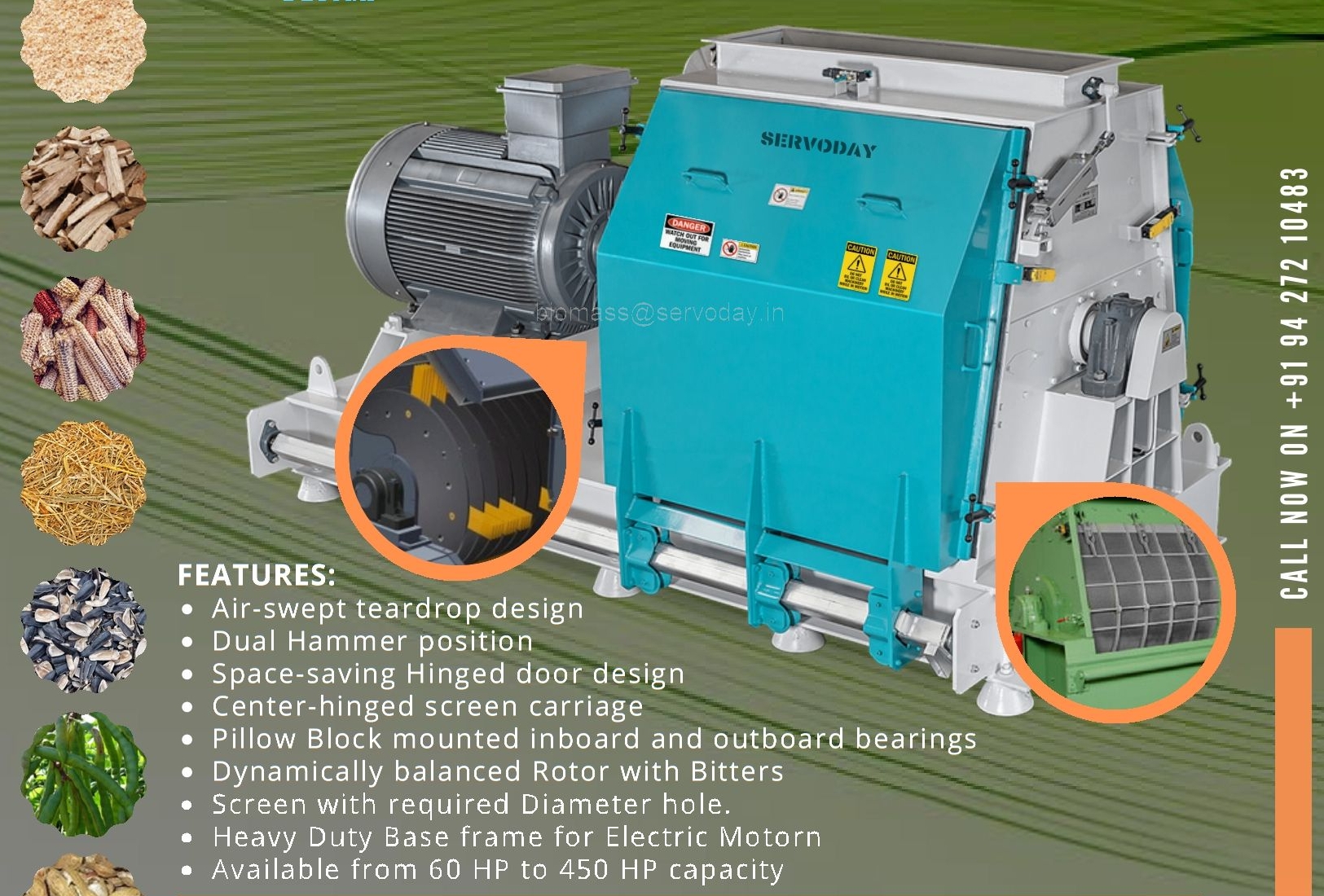

Process Function The Tear Drop Hammer Mill is designed for efficient size reduction of biomass, wood, and agricultural materials. Its unique tear-drop-shaped grinding chamber minimizes air resistance, ensuring high throughput with minimal power consumption. The mill operates with a robust rotor system and optimized hammer arrangement to achieve uniform particle size distribution. This high-speed hammer […]

Process Function

The Tear Drop Hammer Mill is designed for efficient size reduction of biomass, wood, and agricultural materials. Its unique tear-drop-shaped grinding chamber minimizes air resistance, ensuring high throughput with minimal power consumption. The mill operates with a robust rotor system and optimized hammer arrangement to achieve uniform particle size distribution.

This high-speed hammer mill is ideal for pre-processing raw materials before pelletization, improving efficiency in biomass, feed, and industrial applications. The integrated air aspiration system enhances performance by reducing heat buildup and dust generation, resulting in a cleaner and safer working environment.

Technical Features

| Feature | Specification |

| Grinding Chamber | Tear-drop design for reduced air resistance and high efficiency |

| Rotor System | Heavy-duty dynamically balanced rotor for consistent performance |

| Hammers & Screens | Hardened alloy steel hammers with precision-cut perforated screens |

| Material Construction | High-strength carbon steel or stainless steel for durability |

| Air Aspiration System | Integrated dust control for improved efficiency and reduced heat buildup |

| Drive System | Direct-coupled motor or belt drive for optimized energy use |

| Capacity | Available from 1 TPH to 10 TPH depending on raw material and configuration |

| Safety Features | Overload protection, emergency stop system, and explosion venting |

Application

🔹 Biomass Pellet Production

🔹 Wood Processing

🔹 Animal Feed Manufacturing

🔹 Agricultural Residue Grinding

🔹 Energy Fuel Processing

🔹 Industrial Grinding Solutions

Process Raw Materials

📞 Contact Us for Biomass Solutions

📍 Servoday Plants & Equipments Limited

📞 +91 9427210483 | +91 9427210484

📧 [email protected]

🌐 www.PelletIndia.com

👤 Contact Person: Sanjay Masuria

📲 WhatsApp: +91 9427210483

Process Function The Napier Grass Squeezing (Dewatering) Press is designed to efficiently reduce the...

Process Function The Coal Pellet Mill is designed to transform fine coal dust, coke powder, and othe...

Process Function The Boiler Biomass Fuel Feed System is designed for the efficient handling and cont...

Compact & Portable Bamboo and Wood Biomass Mobile Pellet Plant – On-Site Biomass Processing Pr...