upto 5.0 Tons Per Hour

Process Function Refuse-Derived Fuel (RDF) Pellets are high-energy alternative fuels produced from non-recyclable waste materials. These pellets undergo processing to remove moisture, contaminants, and non-combustible elements, ensuring a consistent and efficient fuel source.RDF Pellets offer an environmentally friendly solution for industries seeking to reduce dependency on fossil fuels. With high calorific value and low emissions, […]

Process Function

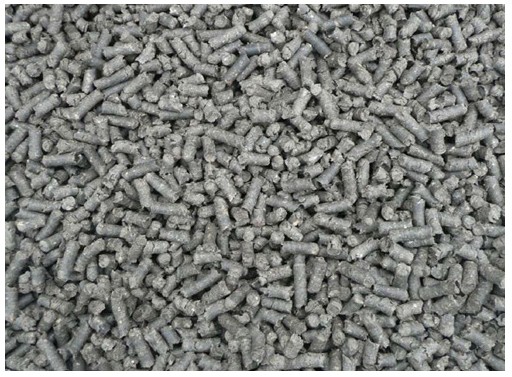

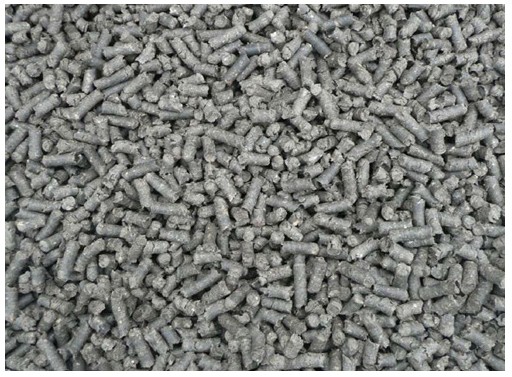

Refuse-Derived Fuel (RDF) Pellets are high-energy alternative fuels produced from non-recyclable waste materials. These pellets undergo processing to remove moisture, contaminants, and non-combustible elements, ensuring a consistent and efficient fuel source.

RDF Pellets offer an environmentally friendly solution for industries seeking to reduce dependency on fossil fuels. With high calorific value and low emissions, they are widely used in cement kilns, power plants, and industrial boilers for sustainable energy generation.

Technical Features

| Feature | Specification |

| Calorific Value | 3,500 – 5,000 kcal/kg |

| Moisture Content | ≤ 12% |

| Ash Content | 5 – 20% (varies by raw materials) |

| Volatile Matter | 60 – 75% |

| Material Composition | Non-recyclable plastics, paper, textile waste, biomass residues |

| Size & Shape | Cylindrical Pellets (Diameter: 6-25mm) |

| Density | 500 – 700 kg/m³ |

| Chlorine Content | < 0.5% (low chloride for reduced emissions) |

Application

📌 Cement Kilns – Alternative fuel for high-temperature combustion

📌 Power Plants – Co-firing with coal to reduce emissions

📌 Industrial Boilers – Sustainable heating for industries

📌 Gasification Plants – Conversion into syngas for energy production

📌 Waste-to-Energy Plants – Reducing landfill waste and generating electricity

Process Raw Materials

RDF Pellets are derived from a variety of non-recyclable waste materials, including:

📞 Contact Us for Biomass Solutions

📍 Servoday Plants & Equipments Limited

📞 +91 9427210483 | +91 9427210484

📧 [email protected]

🌐 www.PelletIndia.com

👤 Contact Person: Sanjay Masuria

📲 WhatsApp: +91 9427210483

Process Function The PelletIndia Twin Screw Breaker (Crusher) is designed to crush biomass briquette...

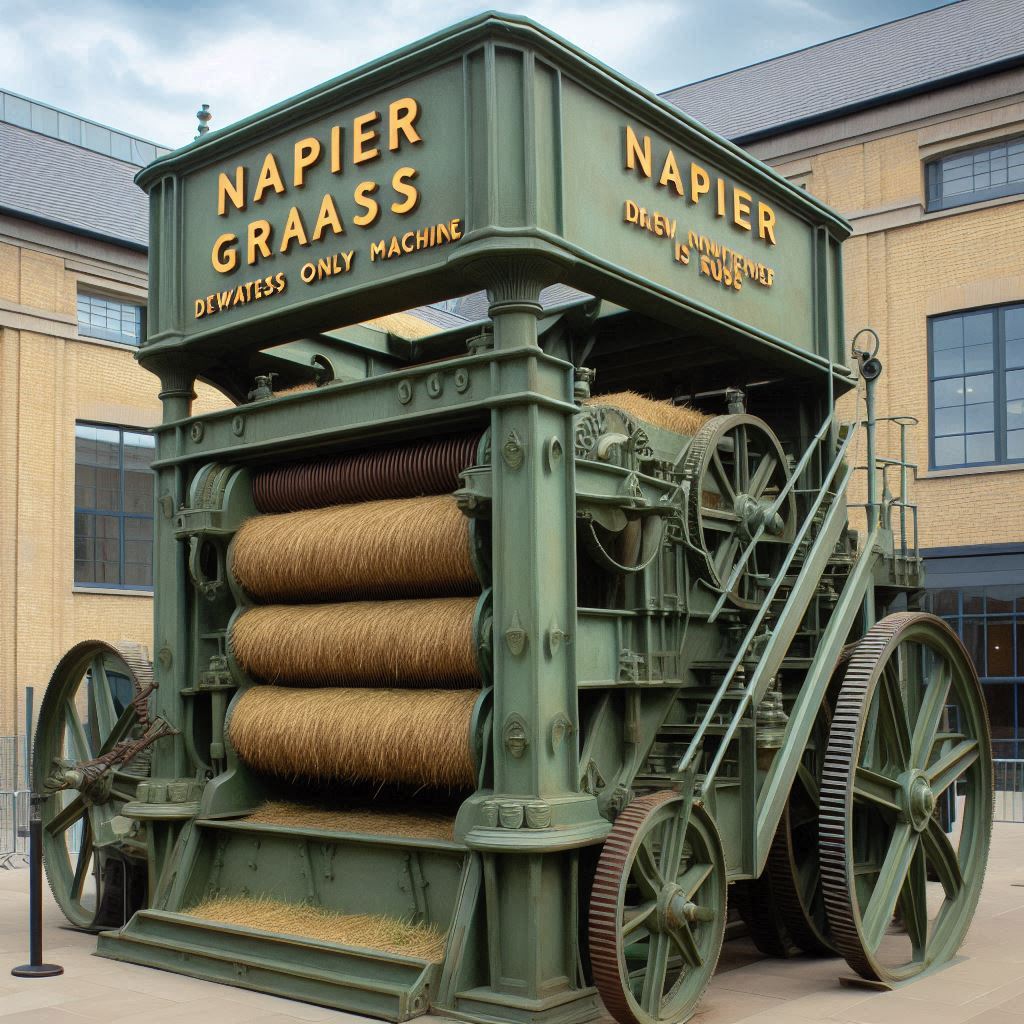

Process Function The Napier Grass Squeezing (Dewatering) Press is designed to efficiently reduce the...

Process Function The Trommel Rotary Screen is a highly efficient screening machine designed for sepa...

Compact & Portable Bamboo and Wood Biomass Mobile Pellet Plant – On-Site Biomass Processing Pr...