customized

Process Function The Silo Storage System is designed to store bulk materials such as biomass, wood pellets, grains, and feed while ensuring optimal preservation and easy material discharge. It enhances workflow efficiency by providing a controlled storage environment, preventing moisture absorption and contamination. These silos are available in various capacities and configurations to suit industrial, […]

Process Function

The Silo Storage System is designed to store bulk materials such as biomass, wood pellets, grains, and feed while ensuring optimal preservation and easy material discharge. It enhances workflow efficiency by providing a controlled storage environment, preventing moisture absorption and contamination.

These silos are available in various capacities and configurations to suit industrial, agricultural, and biomass energy applications. With automated material handling and discharge mechanisms, they minimize manual labor while maximizing space utilization and material safety.

Technical Features

| Feature | Specification |

| Material Construction | Mild Steel, Galvanized Steel, Stainless Steel (304/316) |

| Storage Capacity | 10 – 5000 Tons |

| Design Type | Bolted or Welded |

| Discharge System | Screw Conveyor, Chain Conveyor, Pneumatic Discharge |

| Aeration System | Integrated Ventilation and Dust Extraction |

| Moisture Control | Hermetically Sealed for Moisture Prevention |

| Safety Features | Explosion-Proof Design, Pressure Relief Valves, Fire Detection System |

| Coating | Anti-Corrosion, Weather-Resistant Finish |

| Customization | Hopper Bottom, Flat Bottom, Conical Roof Options |

Application

🟢 Biomass Pellet Storage

🟢 Wood Chips & Sawdust Storage

🟢 Grain & Feed Storage

🟢 Industrial Bulk Material Handling

🟢 Agricultural Storage Solutions

🟢 Cement & Fly Ash Storage

Process Raw Materials

📞 Contact Us for Biomass Solutions

📍 Servoday Plants & Equipments Limited

📞 +91 9427210483 | +91 9427210484

📧 [email protected]

🌐 www.PelletIndia.com

👤 Contact Person: Sanjay Masuria

📲 WhatsApp: +91 9427210483

Process Function Compressed pallets are high-strength, lightweight, and eco-friendly alternatives to...

Process Function The Boiler Biomass Fuel Feed System is designed for the efficient handling and cont...

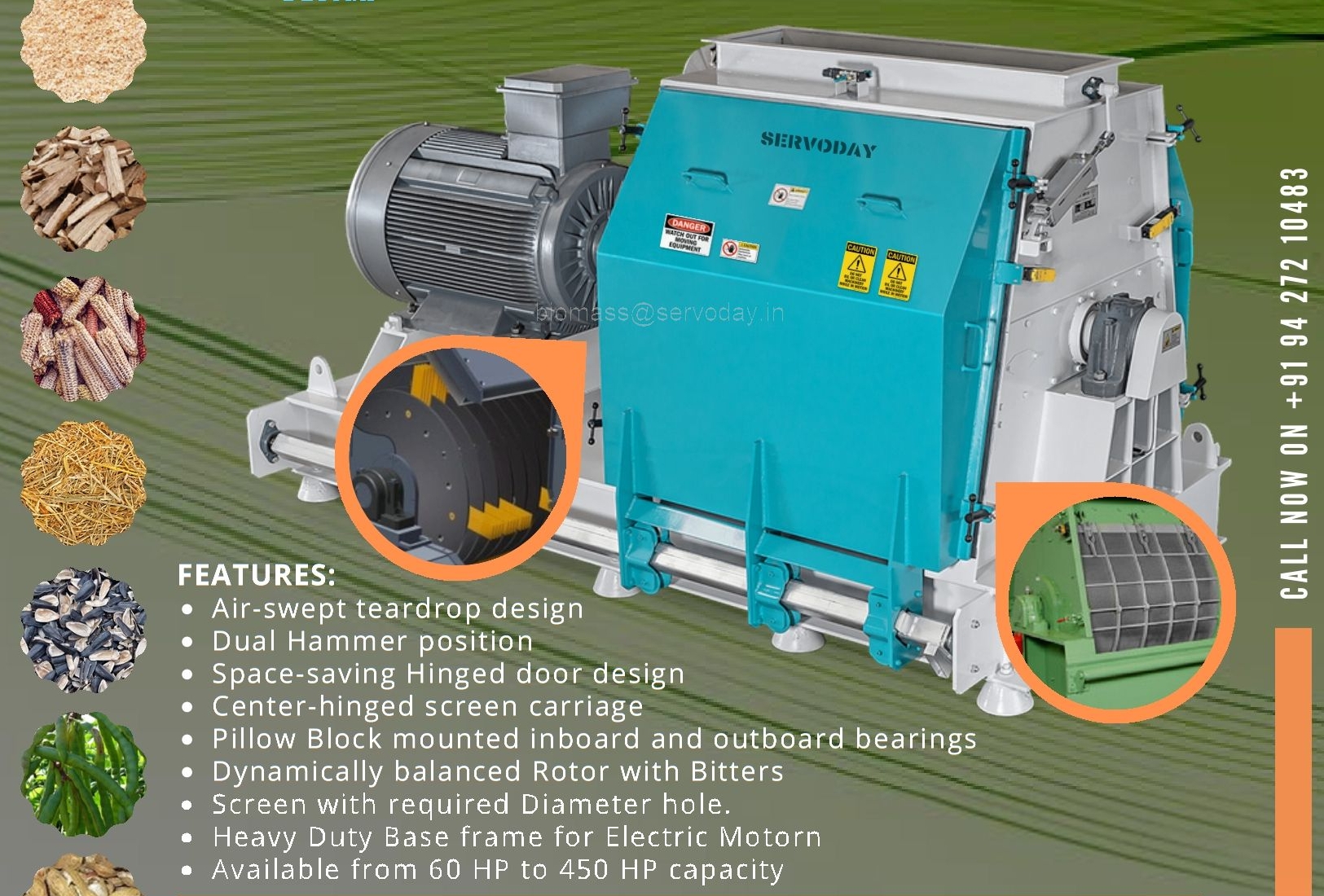

Process Function The Tear Drop Hammer Mill is designed for efficient size reduction of biomass, wood...

Process Function The Trommel Rotary Screen is a highly efficient screening machine designed for sepa...