(Also Known As: Biomass Mixer, Spiral Biomass Blender, Pellet Buffer Mixer)

📘 Description

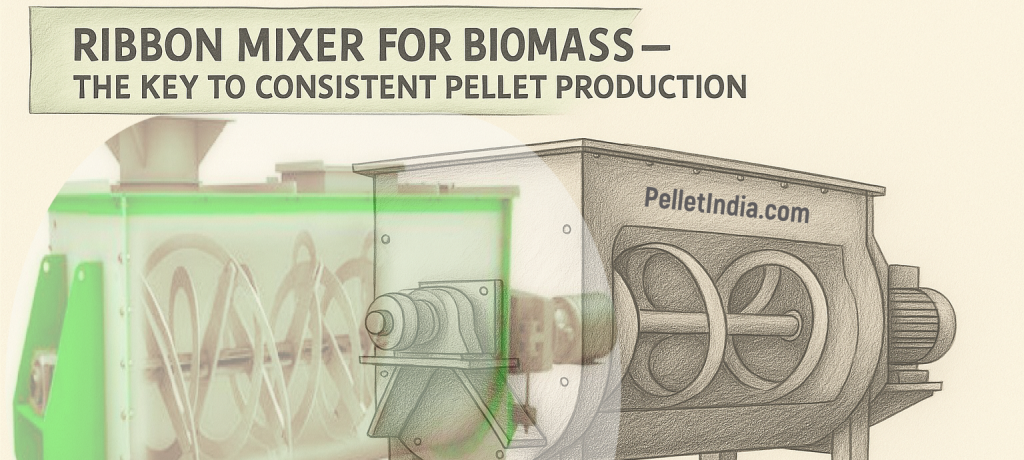

At PelletIndia, with over 25 years of hands-on experience in biomass project design and machinery manufacturing, we emphasize the critical importance of a Ribbon Mixer in any biomass pellet plant. Designed specifically for fibrous and lightweight biomass materials, the Ribbon Mixer ensures proper mixing, feeding, moisture adjustment, and uninterrupted flow into the pellet mill—leading to higher efficiency and longer equipment life.

🔍 Why Ribbon Mixer is Essential in Biomass Pellet Plants

Most low-cost project providers skip this critical component to reduce initial pricing. However, the consequences post-commissioning often include:

🔧 Design Specifics

✅ Key Benefits Summary

🤝 Recommendation to Equipment Purchasers

If you’re investing in a biomass pellet plant (whether 1 TPH or 5 TPH), do not compromise on the Ribbon Mixer. It’s not just a mixer—it’s a backbone component that ensures system balance, improves pellet quality, and increases your ROI through stable operations.

📌 Conclusion

The Ribbon Mixer is not an optional add-on but a mission-critical system in biomass pellet production. Avoid shortcuts during project budgeting that skip the mixer—such omissions lead to higher long-term losses. PelletIndia delivers custom-designed ribbon mixers tailored to your biomass type and production capacity.

⚠️ Disclaimer

Information is based on over 25 years of industry experience by PelletIndia, a division of Servoday Plants & Equipments Ltd. Equipment specifications may vary based on raw materials and plant configurations. Always consult a biomass expert before finalizing your plant layout.

📞 Contact Us for Biomass Solutions

📍 Servoday Plants & Equipments Ltd

📞 +91 9427210483 | +91 9427210484

📧 [email protected]

🌐 www.PelletIndia.com

👤 Contact Person: Sanjay Masuria

📲 WhatsApp: +91 9427210483

From Concept to Commissioning. We are with You.

Our policy is simple and transparent:

No undersized parts, no fraud, no fake components—genuinely serving since 1969. 🚀🔥